Harmonizing with product portfolio and improving UX.

MISSION

Redesign product expression to fit company portfolio.

Improve ease of manufacturing and assembly.

Find and implement UX quick wins.

Reduce product footprint.

METHOD

Interviews and observations with users, manufacturers and production line.

Iterative prototyping, from small to full-scale.

OUTCOME

A product design fitting the brand future vision.

Easier to manufacture and assemble, by reducing part count and optimizing manufacturing methods.

Facilitated internal access for sterilization.

Increased processing power and screen responsiveness.

More space efficient in lab.

CONTRIBUTIONS

Product expression and its detailed design.

Internal mechanisms and lid mechanism.

Leading cross-functional team.

Building and testing proof-of-concepts at various scales.

The look before redesign

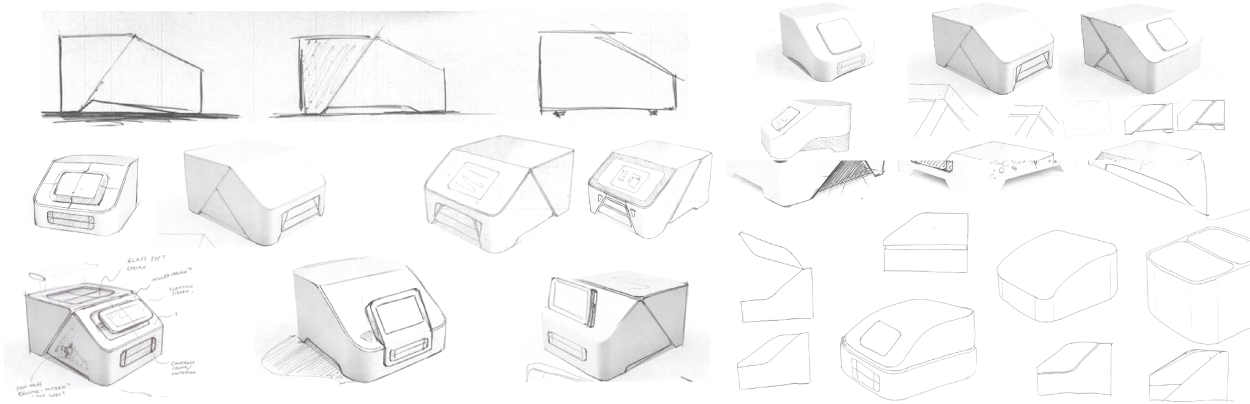

Ideation

Early quick and dirty 3D concepts

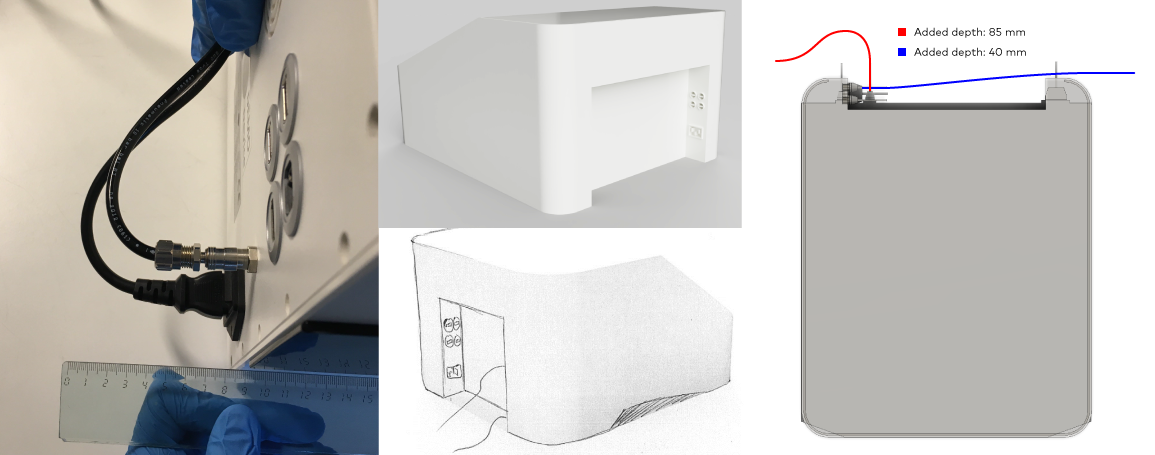

Cable and footprint management

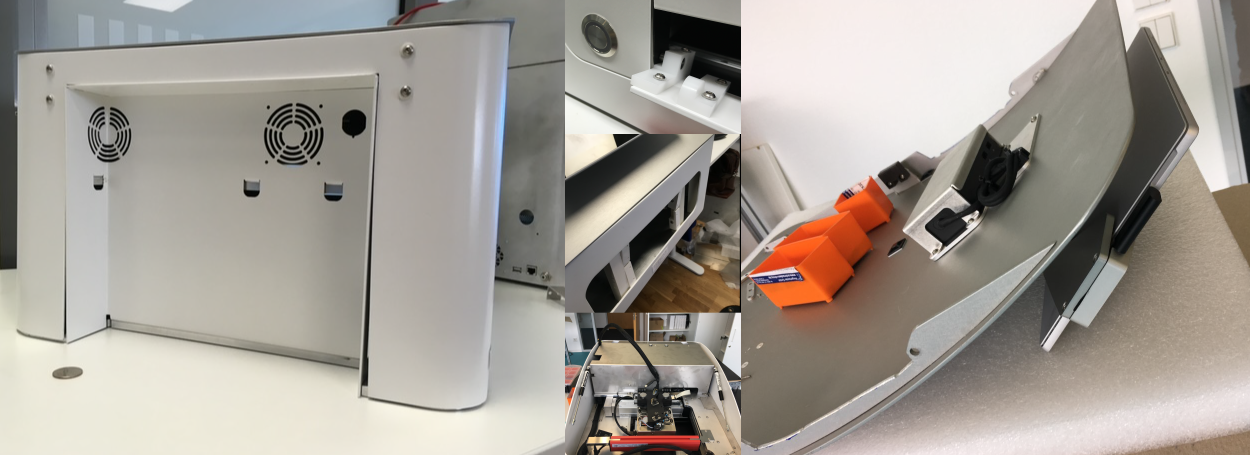

Prototyping custom hinge and gas springs

Full system prototype

The final product in use